Reflection

As the sun comes up...

Looking Back

When we started this project, we wanted a final system that looked and felt like real hardware rather than a rough student prototype. We reached that goal. The finished version is machined, polished, and strong enough to support a camera without wobbling.

We also set out to track a star and hold that position long enough to take a picture. After a lot of trial and error, we were able to point the system at the night sky, lock onto a target, and collect long exposure images. Our first successful photographs were of Sirius and Jupiter, which felt like a major step forward.

We ran into plenty of problems that forced us to learn quickly. Some of us were machining for the first time, others were integrating large software libraries. Machining the cycloidal drive pushed our tolerances more than we expected, and we had to rework parts so the stages would spin smoothly. On the software side, we spent many hours getting the plate solving, camera control, and motor signals to agree with each other.

Looking back, those challenges were the reason the outcome felt rewarding. The system works, it produces real night sky images, and it gives someone new to astronomy a way to start collecting their own observations. We are very proud of our product and we hope that it can inspire other young and new astronomers to build and make their own.

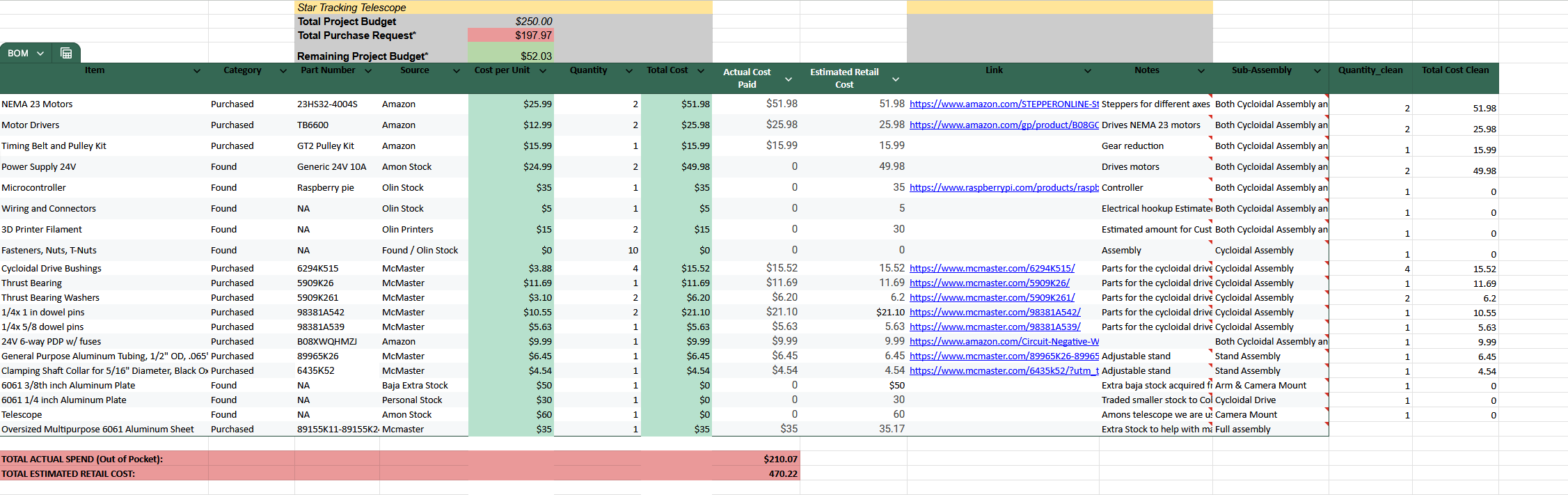

Cost & Materials

Looking at the budget in detail, the full retail cost of our metal build lands around $570, mostly driven by aluminum 6061 plates, bushings, thrust hardware, and a pair of NEMA-23 motors with TB6600 drivers. The camera used would be around 100 on facebook marketplace, however we got it as a loaner from a team member. If a team wanted a low-cost version, the entire mechanical system can be swapped for 3D-printed PLA/PETG parts, which removes the aluminum plate, stock tubing, and machining consumables. In that configuration, you only pay for the motors, drivers, timing belt, a Raspberry Pi, thrust bearings, filament, wiring, and basic fasteners, roughly $225–$275 using our BOM assumptions. A team with access to a printer and a loaner camera could get even closer to $200 all-in, which means you can reproduce the tracking performance without a machine shop. The value of our final version is rigidity and finish, but the core motion system, gearing, and tracking algorithm work just as well in a fully printed enclosure.